Warning: distinctly un-humble and boastful post to follow…

I have made this; my first ever raincoat… :0 and I am thrilled!!!!! with how it turned out!

Making a raincoat is one of the scary things I have always wondered was too hard for me, whether the technicalities were beyond me. Now I have successfully made one I feel like I have achieved another small step toward having an entirely me-made wardrobe.

Thank you so much to all who left a comment regarding good quality raincoat fabric sources 🙂

I checked each and every one of your recommendations.

I found extremely helpful this article written by Caroline, the link sent to me by bloodsweatshoptears. Caroline wrote about making a waterproof cycling jacket and included bundles of relevant and very interesting information for the outdoor-gear sewing newbie like myself. And the jacket she made is so awesomely fantastic and inspiring…

Caroline’s article included a link to another very very informative article on how to choose rainwear, which I read and reread. This article really helped me to honestly assess what I actually wanted from my raincoat… which was: another raincoat almost exactly like my old one!

I had bought my previous old raincoat at Kmart for our eldest son Tim when he was about ten years old. After he had worn it for a coupla years I had to buy him a new official school uniform one, so his old navy blue one became mine. I have worn it and worn it pretty solidly every rainy winter’s day since … and Tim is now 22 years old, so you can see the old raincoat has done very good service! The only reason I am replacing it is because it is finally starting to fall apart…. so, I did a close inspection of the old one to work out what to copy and what I could improve. And this is what I did, and have learnt…

I used my old raincoat to help me draft a new pattern: I didn’t have to chop it up to do this, but this would be an excellent plan for someone who hasn’t done much self-drafting. It has raglan sleeves, a hood and a high, inner collar. I incorporated a few, very minor, fitting alterations and small design improvements at this stage.

I decided my raincoat doesn’t need to keep me warm, just dry; so: waterproof, non-breathable fabric, something like nylon ripstop would be the best. I knew from my old one that this kind of fabric does keep one plenty warm enough in our climate already.

I wanted a full lining in my new raincoat. My husband’s raincoat has a polyester net lining; something akin to the fabric school sports shirts are made of; that is smooth and comfortable and very nice against the skin. I added this to my shopping list.

Now, I am sure everyone is dying to know where I bought this awesomely gorgeous fabric (hehe, kidding!)

Well: I browsed the online fabric stores, and had even bookmarked a few and was pretty much all set to BUY, when, like, the next day, I happened to be passing Spotlight and thought it would be worth going in to check out the separating zips. Well, you never know whether the ones you are buying online are dearer than Spotlight, and I’ve always found their zips, while not plentifully stocked, to be very reasonably priced. And while I was there, I idly checked out the fabrics; and hey, whaddyaknow? Nylon ripstop! The colour selection was not huge, but it was definitely cheaper than any I had seen online, so I picked up some royal blue plus a glow-in-the-dark green for trim, just for fun. Polyester net? They didn’t have exactly the same sort that was in my husband’s raincoat, but they did have some that seemed pretty good, so I picked that up too… Velcro? check! Zips? check! Cording and cord-stops? check and check! Spotlight is a much maligned store, and frequently by me, too 🙂 but I have to eat my words now since they had almost everything I needed! The only thing they did not have was some of that marvellous Seam Grip I have read about to waterproof my seams… but I recalled reading that its primary use is in tents and camping stuff, and barely 50m away from the front door of my Spotlight is a BCF store (Boating Camping and Fishing); practically next door. So I popped in, and yes of course they had Seam Grip. I promptly bought some. I was all set!!

The nylon ripstop can be cut just with ordinary household scissors, so I did not blunt my good dressmaking shears on it… bonus!

One can’t use pins willynilly since it has to be waterproof! But when necessary I pinned within the seam allowances.

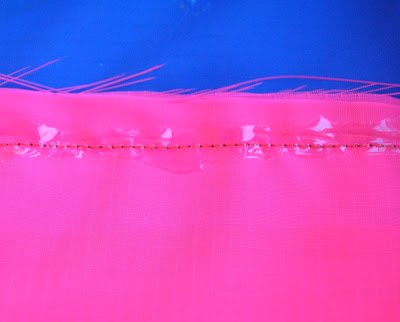

Not for looks (since the raincoat is fully lined) but for extra waterproofing, I sewed all the seams as French seams; bar some of the internal pocket seams which are inside the coat and so are not a waterproofing issue.

I ironed the seam allowances “up”, against gravity (another waterproofing tip) before topstitching in place.

Seam Grip is messy stuff. Apparently it is the best product around for this job, but check out the fine print; it contains toluene. This is nasty… back in the dark ages when I was an analytical chemist I would have only opened a bottle of this substance in a fume-cupoboard. Not having access to a fume cupboard anymore, I worked outside and used disposable rubber gloves. I cloaked Bessie in plastic bags to protect her (not that she is susceptible to carcinogens….) and draped and pegged my half-finished coat inside out to do the seam sealing.

I left it to cure for 12 hours, and kept on going out regularly to pull apart the bits like the underarms, that were sticking to themselves; to ensure nothing became permanently glued together. Even when fully set I have found the Seam Grip has a tendency to stick to itself. Having the lining in has alleviated the problem somewhat, but not completely. I sure hope it de-stickifies eventually :S

Ventilation: meaning, an aperture for one’s body heat to escape outside; is a must in waterproof non-breathable garments. So I copied a feature from my old raincoat and hammered in two eyelets under each of the arms, at the back. These, as well as the eyelets in the hood for the cording (pictured below), are each re-inforced on the inside with an extra four layers of self-fabric, for strength.

Quick and simple velcro-lined tabs to tighten the wrists. I’ve used something like these on my old raincoat for the last dozen or so years: so they’re second nature to me and I am accustomed to them, so I copied them exactly for my new one. No need to re-invent the wheel, right?

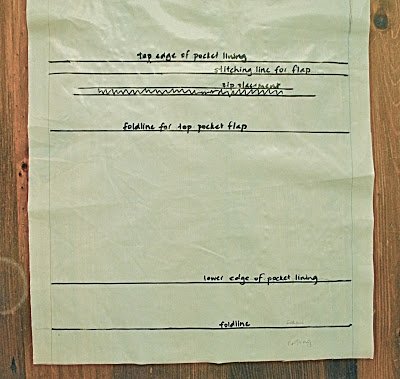

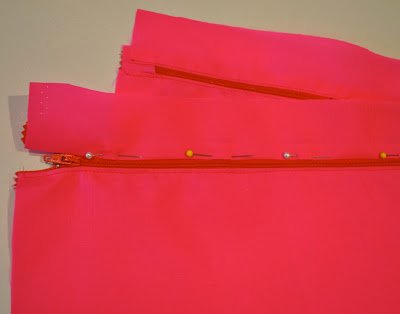

Waterproof pockets; an essential. These have a full-width flap that is an extension of the upper front, covering a zippable pouch that is an extension of the lower front. These are similar in design to the ones on my old raincoat; I simply extended them so they are much wider, thus eliminating seams. In fact, at the sides they extend out to and in to, the side seams and the front placket. Less stitching therefore simpler to construct and finish off, and you get wider pockets! What’s not to love about that? (I can do a tute on these pockets, if anyone is interested. I’m frankly a bit terrified of doing tutes now, but I am pretty chuffed with how they turned out, so please let me know, ok? 🙂 )

This has been a fun learning curve.

Of course, eagle-eyed Perth readers will instantly see that I could not possibly have taken these photos during the last 4 days, since it has been unrelentingly sunny. Truth: I raced out to take these during some early morning showers last Wednesday, but have been too apathetic to even look at my photos since then, let alone write up this post. But anyway, here we are. And I am sure we will get more rain soon. Hopefully.

And yes, flushed with my own sewing success, another raincoat is already in the pipeline, this one for Cassie…. 😉 stay tuned!

Details:

Raincoat; self-drafted, with the help of an old one, nylon ripstop with polyester net lining

Skirt; Vogue 1247 lengthened and lined, red cotton velveteen ombre dyed brown, details here and my review of this pattern here

Leggings; self-drafted, red cotton jersey, details here

Boots; Andrea and Joen, from Uggies in Dunsborough (now renamed Eco-boutique)