I’ve made some shoes!!! This is my first foray into “proper” footwear. Yeah, I made slippers recently, but I’m not counting those. And technically these are slides, which are pretty basic things on the shoe scale, really.

But still. They are real shoes! Wooooooooooooooo!

ok, I’m sorry, calming down now. I’m just a bit excited about them 🙂

So, for ages I’ve dreamt longingly about having a go at making my own shoes. However cool stuff like shoe-making courses are just not on offer here in Perth. Well that’s just that and it can’t be helped, but life is too short to not do stuff that you really want to do, right? so I just decided to GO FOR IT! havva go, just DO it, whatever, even without a teacher or the tools or even the faintest idea of what I was doing.

The choice of denim; well every time, and I mean every time my friend J and I go out on girly shopping trips, as we head into our favourite shoe stores I say for the eleventy-billionth time; “ooh, I really would like a pair of denim- or denim-coloured shoes.” I’ve often though they would be sooooo useful and would go with a lot of my wardrobe. I mean, we all know denim jeans go with everything, right? So, it stands to reason, denim shoes should go with everything too. And; quick aside; honestly, why has that thought not occurred to shoe-makers yet? Because so far my search for denim-y shoes has been one big, long, mournful FAIL. It’s sad, but they are a non-existent beast. Or should that be a pair of non-existent beasts, maybe? I still wanted them though.

And now I have some!

Now; before I introduce my procedure for making these, obviously I am no expert and I have no idea what I’m doing. I’m making it up as I go along with educated guesses, and I don’t have the proper equipment, like lasts or an industrial sewing machine. I’m sure shoe-making experts would look at my efforts here and roll about, laughing helplessly at how awful they are. It’s true, they are far from perfect. Hopefully I can improve!

For the bases I used two balsa wood blocks from Bunnings; chosen mainly because I spotted them and it seemed like a good idea at the time. I drew a template of each of my feet, overlaid/combined them to draw a single “master” template. I used a coping saw to cut out the main chunks and get the right shape; and then three sheets of sandpaper to smooth and contour, ranging from super rough to light. I used the roughest sandpaper to do most of the contouring for my foot pads and heel pads to sit in the base nice and snug and comfortable.

Shaping/contouring the wooden bases to be equal-sized and -shaped mirror images to each other and to fit my feet was the MOST time consuming part of the whole thing. Really, ten progress photos slotted in here would be a fair and accurate representation of this step rather than just one; but that would be extremely boring, so just a few then…

I used an pair of old jeans for the denim.

I cut long strips for the side coverings, and topstitched the ends down using orange thread, to match the orange thread usually used in jeans topstitching. Glued it in place using PVA exterior wood glue. I chose this glue because it was not too quick-drying therefore easy to work with, and yet is still super hardwearing and durable and dries to a hard, water-resistant finish. Not waterproof, mind you. NOT that I’m planning to wear my shoes to slosh about in puddles or anything like that, aiyiyi perish the thought!

Clipped the curves etc, to minimise overlapping, so the edges would lie as flat as possible; and glued them down, upper and under.

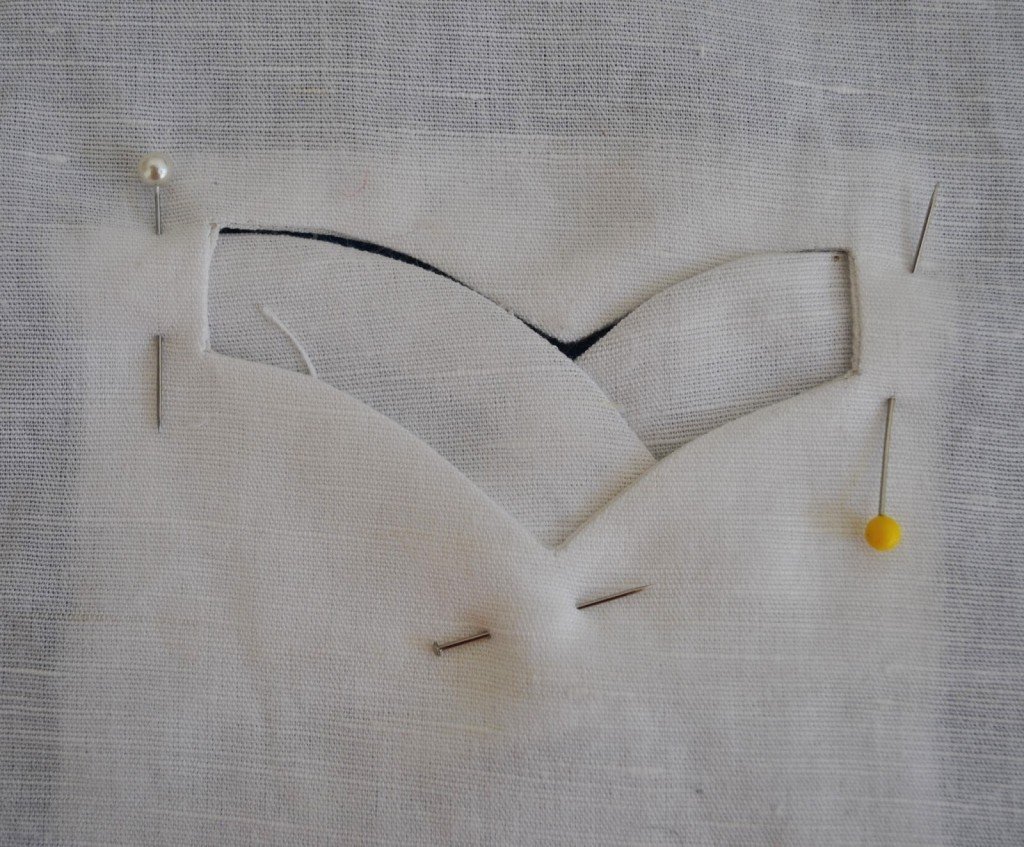

Made a template for the top bits via the auditioning of a thousand “muslins”; well, not really, but it felt like it. The winning design was cut so as to make a feature of the existing jeans’ side seam with the allowances double top-stitched down in that distinctive shade of Levi’s orange. The tops are double layered; lined with plain denim, sewn right sides together then turned out and under-stitched. The excess at the sides was trimmed to wrap right around underneath my foot then glued in place.

I made a padded insert by trimming a purchased foam shoe insert from Coles to fit, then stitching to a piece of denim around the edge using orange thread. The ends were clipped, turned under and everything glued in place.

I covered the curved part of the sole with denim…

Finally, I cut thick rubber floor matting (Bunnings) to fit the soles using a stanley knife, and glued this in place. This will be quite hard-wearing and will stand up to a lot of knocks, hopefully.

Making these was an interesting experiment, and a learning exercise in how not to do a few things. Yes, a second pair of shoes is in the pipeline already. My second pair will definitely be better, I think. My first mistake; balsa wood does not hold nails, thus the need for lots of glue. I’m definitely going for harder wood and nails in the future.

The big question for me is: am I going to dare to actually wear my shoes? outdoors? like, for a full day? well today I almost did since I was meeting my same friend J for lunch, and I thought they went really nicely with my outfit… but then I chickened out! Too many puddles around from the recent rain :S

Maybe I’ll just keep them exclusively for me-made May, haha! 😉

No, of course I’ll wear them, but it’s going to be hard to avoid babying them. I’m ridiculously pleased with them. Well so far, until I can make something better anyway!