Oh boy. I’m not sure if I have done it right, but I’ve just created my first pattern and put it onto Burdastyle as a free downloadable pattern!

If you want you can download the pattern here… you have to click on “print pattern at home” to get the instructions, which form part of the pdf…

So OK, it’s just for a tie (baby steps, here), but it still took me … er, hours. Actually far far longer to draw and write up the darn pattern than to make up the tie…!

Obviously, please let me know if there are any problems with it and I will sort them out as best I can 🙂

Anyhoo…

So, during the month of June we had Tim’s birthday party, and he asked me if I could make him a tie to wear. Tim has very firm ideas on his apparel, and always has to look sharp. Hmmm, where did he get that one from, I wonder…

He had his heart set on a definite colour, and since I had mentioned oh-so casually once upon a time how a tie would be laughably easy to make, and a darn sight cheaper to make your own than the $60 odd you get charged for RTW, even polyester, he put in his request.

So, I have taken apart one or two ties in my time (the last time to make

this), and they are pretty easy to make, but I took a few progress shots to show here, so if you haven’t made one before you don’t have to take apart your own tie natch, to find out…

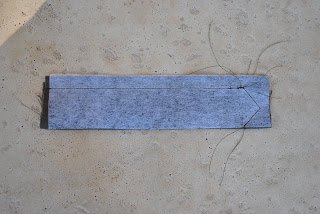

Firstly, a tie has four different fabric components, the outer fashion fabric, lining fabric, padding fabric, and a section of very lightweight underlining fabric.

I used:

For the fashion fabric the lovely rich egg-yolk yellow silk dupion Tim had chosen

scraps of lightweight turquoise cotton for the lining

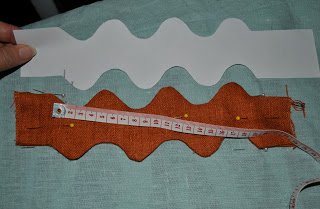

A strip of corduroy for the padding

scrap of organza for the underlining

The underlining is pinned in place onto the wrong side of the tie, this is presumably to avoid stitching lines appearing on the outside of the tie.

To get the nice mitred top and bottom edges of the tie, which is a nice finish ensuring that the lining fabric will not peep out from around the edges of your finished tie; I sewed the triangular lining pieces on as follows…

Firstly, fold the tie lengthwise in half, and sew a short line of stitching, perpendicular to the centre fold of the tie… starting at the centre fold and finishing at about 5mm from the raw edges. The pin is laid in place alongside the white stitching line.

Note: this is a demo scrap that I sewed up later to show up that stitching line properly, really your underlining fabric should be in place wrapped around on the outside of this fold. I did take a photo with the underlining in place, but my white thread didn’t show up very well against the white underlining fabric, so took these mock-up photos separately, without the underlining.

Lay the triangular lining piece over and stitch to the fashion fabric, each line of stitching ending right at the end of your short stitching line, that you did in the previous step.

Turn out, and you have a nice mitred corner. Do both the top and bottom of the tie in the same way…

Now insert the padding into the points of the tie. This requires some gentle stuffing and poking the padding point up cleanly and firmly into the corner; I know there are proper tools for this job that proper seamsters use but I usually use a slightly blunted pencil (hehe, oops!) I had cut my padding a tad long, just in case, and so there was some trimming required here to get it all sitting in nice and flat.

Then just fold one long edge in and press firmly in place the length of the tie.

The last open edge, fold in the seam allowance, then fold over the centre of the tie and press.

Slip stitch that long folded edge in place, and down those short slanted edges onto the lining.

Voila!